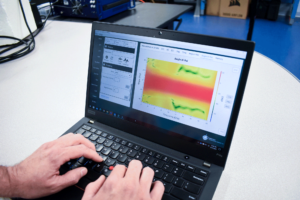

The focused beam system uses microwave lenses to focus microwave energy (2 GHz and up) onto a material specimen. The microwave transmission and reflection are measured, including both amplitude and phase, which then determines the intrinsic dielectric and/or magnetic properties of the specimen. A microwave lens system can also measure diffuse scatter or radar cross section (RCS) of a small target.